Manufacturing Execution Systems (MES) have been the secret advantage of large manufacturers since the early 90’s, and they have reaped the benefits of lower manufacturing costs and higher profits. The good news is that everything has changed in the last decade. Whether you call it a technological revolution, Industry 4.0 or some other buzz word, it can’t be denied that a change is occurring. Software and protocols have improved drastically, automated data is available from all areas of the facility, and the financial entry point for MES systems has become attainable.

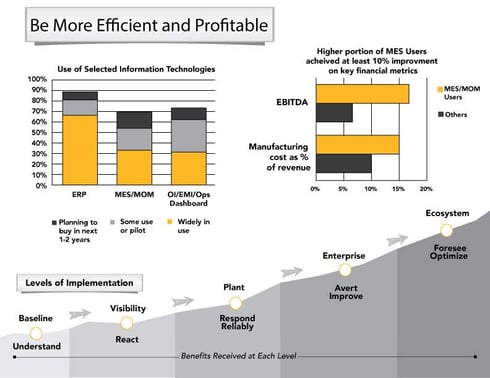

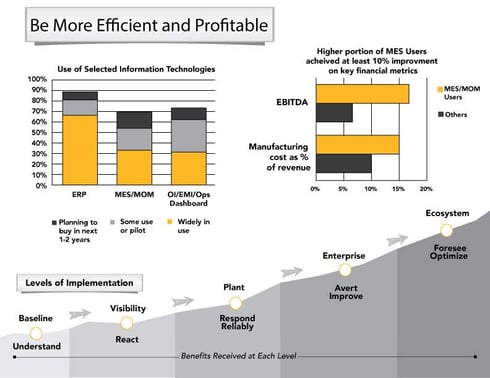

Let’s boil it down to how it affects your business. You can improve your situation, and be more efficient and profitable.

Don’t get data for the sake of having data. You are seeking value—true and measurable value. It is possible to have real-time business measurements, real-time business empowerment and real-time business improvement. Through an in-depth and comprehensive study of MES users, MESA International reports these benefits as the value generators:

- Reduces manufacturing cycle time.

- Reduces or eliminates data entry time.

- Reduces work-in-process inventory.

- Reduces lead times.

- Reduces paperwork between shifts.

- Improves product quality.

- Eliminates lost paperwork/blueprints.

- Empowers plant operations people.

- Improves customer service.

- Responds to unanticipated events.

There are phases of maturity with any MES or metrics programs you institute that start from simple visibility to the ability to predict and optimize performance.

Start Somewhere.

Our number one recommendation is to implement OEE and Downtime Tracking. It is a good entry point to MES, and the rest of the systems and measurements are scalable from this foundation. If you are looking for an even quicker means of trying out manufacturing intelligence, then pick a few KPIs and automate the gathering and distribution of this information.

What more? Check out this white paper to learn about nine MES tools you can incrementally implement to improve data flow, make educated and strategic improvements, and ultimately improve performance.

COMMENTS